Boosting Efficiency and Quality in Cannabis Pre-Rolls: A Deep Dive into PreRoll Press Machines

The Rapid Rise of the Commercial Pre-roll Machine Industry

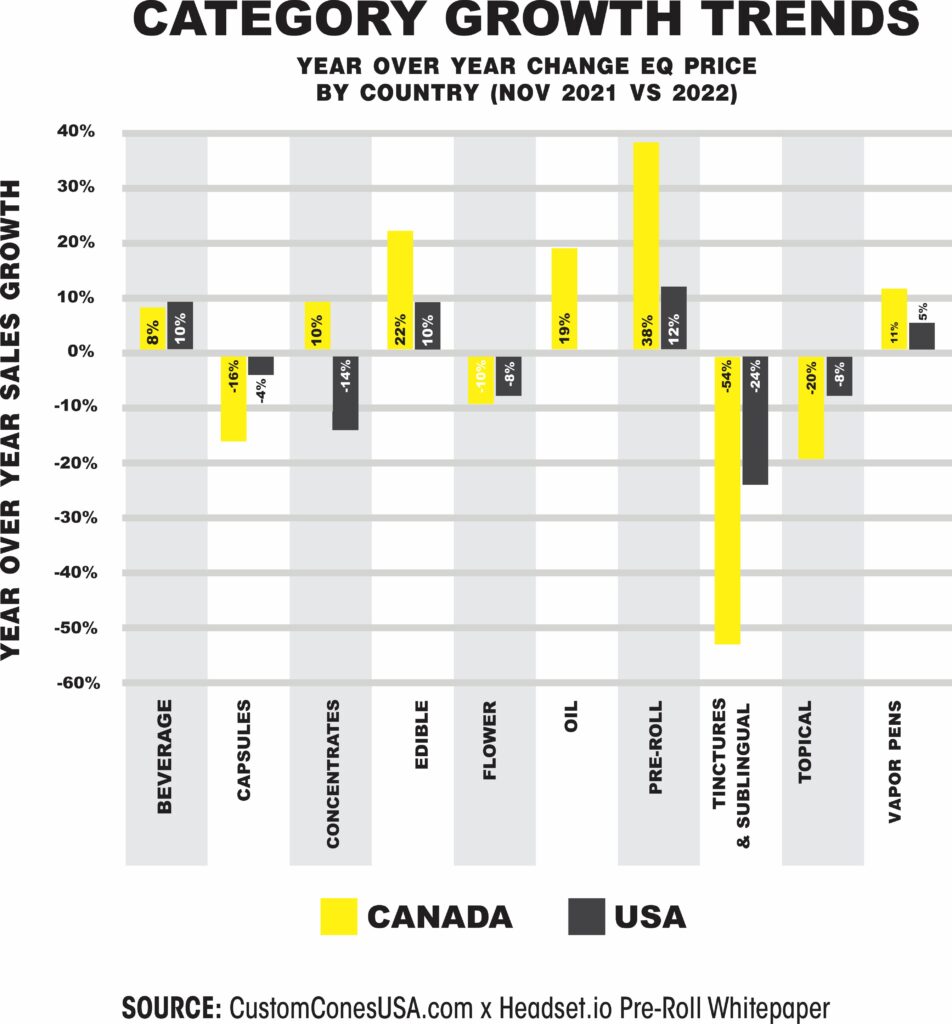

In recent years, the pre-roll market has become one of the most dynamic segments within the cannabis and hemp industries, consistently outpacing other product categories. Since 2020, the pre-roll sector has seen an impressive 50% year-over-year growth, driven by consumers’ preference for ready-to-smoke products that offer convenience and quality. This rapid expansion has opened exciting opportunities for cultivators, processors, and brands looking to establish or strengthen their footprint in a flourishing market.

But as demand skyrockets, so too do the challenges for producers. While pre-rolls offer a high return on investment due to their enduring popularity, scaling production to meet this demand is no easy feat. Traditional hand-rolling methods are labor-intensive, costly, and difficult to maintain at high volumes—putting pressure on businesses to find innovative ways to maximize efficiency while maintaining quality.

Enter the commercial pre-roll machine: a game-changer that is transforming the landscape of pre-roll production. By automating the filling, packing, and closing processes, these machines enable brands to increase output without compromising on quality. A well-chosen commercial pre-roll machine can drastically reduce labor costs, enhance production consistency, and ultimately boost profit margins.

For forward-thinking cannabis and hemp producers, investing in a high-quality pre-roll machine isn’t just a decision—it’s a strategic move to stay competitive in a fast-evolving industry. As the demand for pre-rolls continues to climb, businesses that embrace automation and scalability will be best positioned to capture their share of the market and deliver products that keep consumers coming back.

What is a Pre-roll Machine?

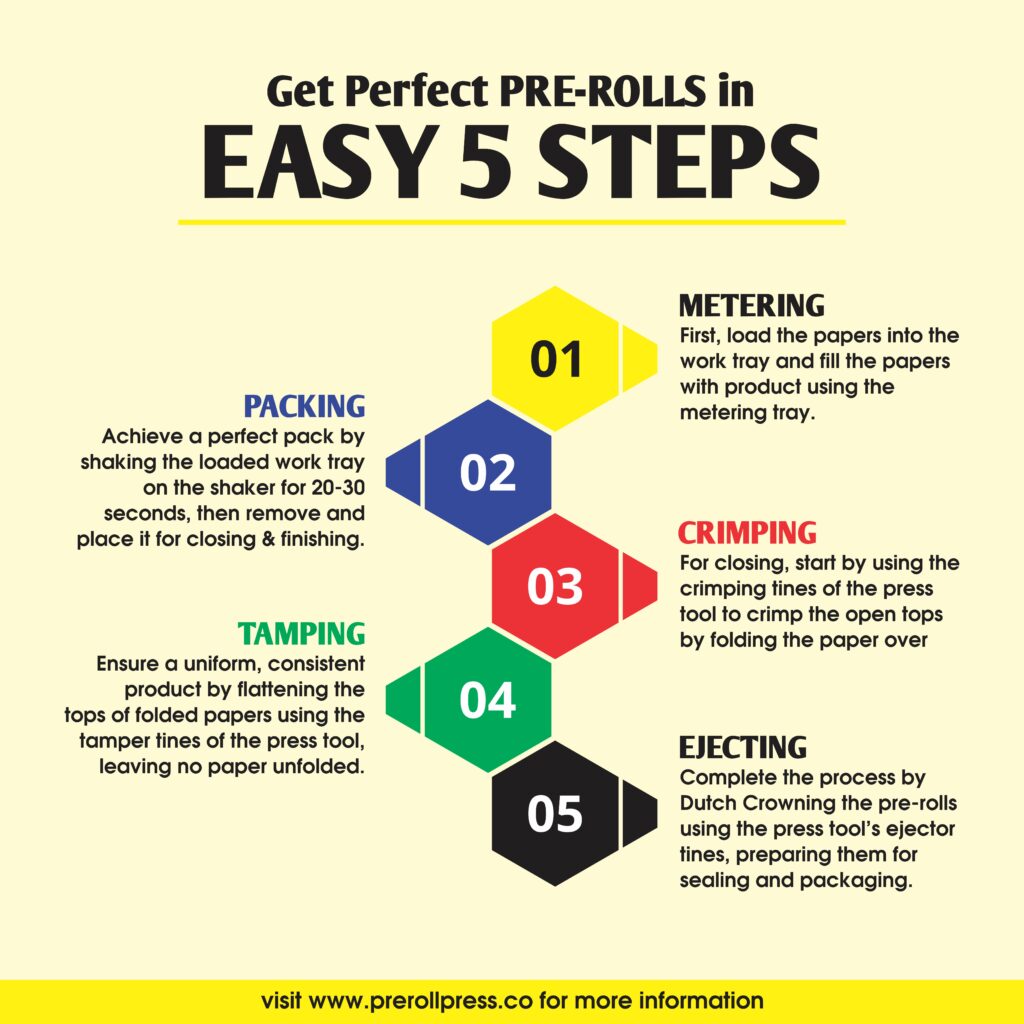

Commercial pre-roll machines are revolutionizing the production process, transforming what was once a time-consuming, manual task into an efficient, streamlined operation. At their core, these machines are designed to automate the filling and closing of pre-rolled cones, enabling businesses to produce high volumes with greater speed and consistency.

Gone are the days of assembling a team to fill and close each cone by hand. A well-engineered pre-roll machine can process hundreds—even thousands—of pre-rolls per day with minimal labor, making high-output production a reality for businesses of any scale. Whether a company is looking to produce artisanal, small-batch pre-rolls or meet the demands of a large-scale operation, today’s commercial pre-roll machines are essential to achieving efficiency without sacrificing quality.

With technological advancements, many pre-roll machines now offer customizable features, allowing operators to adjust filling density, cone size, and production speed. These machines can also adapt to various paper sizes and cone styles, making it easy for businesses to produce everything from standard cones to specialty “Dog Walkers” with minimal hassle. By incorporating automation, brands can focus less on labor-intensive tasks and more on crafting premium pre-rolls that attract loyal customers

How to Find the Best Commercial Pre-roll Machine

Choosing the right pre-roll machine is crucial for any business aiming to scale its production. While it may seem like comparing basic features—such as speed, capacity, and warranty—can lead to a decision, there are many nuanced factors that can impact a machine’s fit within your specific workflow.

For instance, while some machines boast impressive speeds (like filling 100 pre-rolls in under a minute), the full production process often involves additional steps, such as loading cones into the machine and closing them post-filling. These auxiliary tasks can add considerable time and may require extra hands. Before committing, it’s essential to assess the true efficiency of a machine by understanding its complete workflow requirements.

Consider the following criteria when choosing a pre-roll machine:

- Production Capacity: Does the machine’s output meet your current demand, and does it allow room for scaling?

- Labor Requirements: How many employees will you need to operate the machine effectively? Look for a balance between speed and labor savings.

- Integration: How easily does the machine integrate with your existing production setup?

- Versatility: Can it handle different cone sizes and filling densities to meet varying consumer preferences?

- Ease of Maintenance: Machines that are easy to clean and maintain reduce downtime and ensure consistent performance.

By focusing on these factors, you can choose a pre-roll machine that not only delivers on speed and quality but also aligns seamlessly with your business’s unique production needs.

Why Choose PreRoll Press Inc.?

At PreRoll Press Inc., we are more than just a manufacturer of pre-roll machines; we are industry innovators with deep roots in cannabis cultivation and processing. Founded in 2015 in Spokane, Washington, our journey began with Yield Farms, a small-scale cannabis farm that gave us firsthand experience in the challenges and demands of the pre-roll industry. With this knowledge, we designed and developed our own pre-roll machine to address labor challenges and enhance production efficiency.

Today, PreRoll Press Inc. stands out for our commitment to quality, consistency, and innovation. Our machines are built to help cannabis and hemp businesses achieve more—by lowering production costs, boosting output, and maintaining a level of quality that delights customers. Unlike typical machines that focus solely on cone-filling, our patent-pending technology allows for both filling and closing cones quickly and efficiently, giving our customers a comprehensive solution that saves both time and money.

Why PreRoll Press? Because we combine cutting-edge technology with a practical understanding of the industry, empowering business owners to produce high-quality pre-rolls that stand out. From our focus on durability to our emphasis on seamless workflows, we are here to elevate your production process every step of the way.

Efficiency with Our Commercial Pre-roll Machines

In the fast-paced world of pre-roll production, efficiency isn’t just a benefit—it’s a necessity. At PreRoll Press, our commercial pre-roll machines are designed to handle the high output that today’s market demands, producing up to 121 joints in less than 10 minutes. Compared to hand-rolling or other machines that require lengthy manual input, our machines eliminate bottlenecks and ensure a smooth, uninterrupted workflow.

The days of endless hours spent on manual production are over. Our machines are engineered to streamline every part of the process, from filling and closing to packing, so you can focus on growing your business rather than managing labor. With our machines, a single operator can oversee production, making it easy to scale up without adding significant labor costs.

In an industry where time and labor translate directly into profit, PreRoll Press Inc. stands as a powerful ally in helping businesses meet their production goals efficiently and cost-effectively.

Meeting the Growing Demand: Scalable Solutions for a Competitive Market

With the cannabis and hemp industries on a steady upward trajectory, pre-roll demand shows no signs of slowing down. Analysts predict that pre-roll sales will continue to grow, driven by consumer preference for convenient, ready-to-use products. In an increasingly saturated market, businesses that scale effectively are positioned to capitalize on this growth, and PreRoll Press Inc. provides the tools to do just that.

PreRoll Press machines are built to support businesses at any stage—from emerging brands to established enterprises ready to scale. Our machines are designed with future growth in mind, offering adaptability and volume capacity that allows your operation to keep pace with market demands. Whether you’re fulfilling large wholesale orders or scaling up direct-to-consumer sales, our high-capacity machines streamline production without compromising quality.

For cannabis brands looking to expand, PreRoll Press machines offer unmatched efficiency, allowing you to meet high-volume orders and respond to seasonal surges with ease. By investing in machines that grow with your business, you’re positioning yourself not just to survive but to thrive in a competitive, expanding industry.

Quality Assurance: Precision Engineering for Consistency and Purity

Quality assurance is at the core of every machine we design at PreRoll Press Inc. Our machines are engineered to provide consistent, perfectly packed pre-rolls that maintain their integrity through handling, transport, and use. This precision translates directly into an enhanced experience for consumers, who can count on a smooth, even burn every time.

Our quality assurance measures start with the materials. Each PreRoll Press machine is constructed from high-grade, food-safe materials that are easy to sanitize, minimizing the risk of contamination and ensuring product purity. Our machines’ precision engineering also means reduced variability, so each pre-roll is uniform in density and quality, helping prevent issues like “canoeing” and uneven burns.

Beyond build quality, PreRoll Press machines are designed to limit human contact, which reduces the chance of contamination and enhances the overall cleanliness of the production process. This attention to detail not only improves the aesthetic appeal and usability of the pre-rolls but also builds trust with consumers seeking a premium experience.

Types of Commercial Pre-Roll Machines: Custom Solutions for Every Need

PreRoll Press Inc. offers a range of machines tailored to suit various business models, production needs, and customer demands. Here’s a closer look at each machine type, along with the unique scenarios they cater to:

- Press 121 Series:

- Overview: Designed for high-volume production, the Press 121 Series can fill and close up to 121 pre-rolls in under 10 minutes, making it ideal for large-scale operations.

- Best For: Wholesale producers, dispensaries, or brands focused on high-output, multi-size production (109mm, 98mm, 84mm, 70mm).

- Special Features: Color-coded machine models for easy size identification; adjustable for various cone densities and weights.

- Press 100 Series:

- Overview: Compatible with existing systems like the Futurola Knockbox and Thumper, the Press 100 is an add-on solution that enhances production speed and quality by automating cone closing.

- Best For Businesses that already own filling systems and want to add quick, reliable cone-closing capabilities to boost production efficiency.

- Special Features: “Dutch Crown” closure option for a professional, tamper-proof finish, and faster production times.

Each model offers customization options, allowing businesses to adapt their machines to specific sizes and weights to match product offerings. This versatility empowers businesses to stay flexible and responsive to market trends while maintaining efficient, high-quality production.

Competitive Pricing: Affordable Quality with Long-Term Savings

At PreRoll Press Inc., we believe in providing premium, durable machines without the premium price tag. Our commitment to affordability means that we offer some of the most competitive prices in the industry, ensuring businesses can scale up production without straining their budgets.

Cost Analysis and ROI: PreRoll Press machines provide a rapid return on investment. Most clients recover their costs within a matter of weeks thanks to reduced labor expenses, high production volumes, and increased efficiency. With lower maintenance needs and durable construction, our machines keep costs down over time, translating into higher profit margins.

Pricing Transparency: Our transparent pricing structure includes an itemized breakdown of machine features, ensuring that you know exactly what you’re investing in. By offering high-quality equipment at competitive prices, PreRoll Press enables you to maximize your investment while delivering consistently superior products.

Extensive Product Range: Everything You Need for End-to-End Production

PreRoll Press Inc. is more than just a machine provider; we’re your comprehensive partner in pre-roll production. Our extensive product range includes not only high-capacity pre-roll machines but also a variety of add-ons and accessories to optimize your production process:

- System Add-Ons: Enhance production efficiency with cone sifters, metering trays, and metering adjustment plates that allow for precision packing and reduced product waste.

- Production Accessories: Essential tools like tube brushes, catch trays, and scrapers make cleaning and maintenance quick and easy, ensuring uninterrupted operation.

- Preferred Papers and Cones: Choose from our curated selection of high-quality rolling papers and cones, optimized for use with PreRoll Press machines to provide consistent results and a premium consumer experience.

Our one-stop-shop approach ensures that you have all the components you need to maintain, upgrade, and optimize your production, from raw materials to specialized tools.

Lifetime Quality Assurance: Peace of Mind with Every Purchase

When you purchase a machine from PreRoll Press Inc., you’re investing in more than just equipment—you’re gaining a trusted partner committed to your long-term success. We offer a limited lifetime warranty on our machines, a testament to our confidence in their durability and performance.

Our warranty covers core machine components and provides access to expert customer support, training, and troubleshooting. Every PreRoll Press machine undergoes rigorous quality checks before shipping, ensuring that you receive a machine that’s ready to perform. Here’s an example of how our warranty has benefited clients:

Case Study: A high-volume dispensary in Colorado invested in a Press 121 machine and, within months, experienced a surge in orders. When their machine needed a tune-up, our support team promptly assisted, providing replacement parts and guidance. This responsive support allowed them to keep up with demand, cementing their trust in PreRoll Press’s commitment to quality.

With PreRoll Press Inc., you’re backed by a partner who values your success and provides lasting assurance, so you can produce with confidence and keep your operation running smoothly.