The Ultimate Guide to Infused Pre‑Rolls (2025): Trends, Sizes, Preparation, Equipment and Infusion Techniques

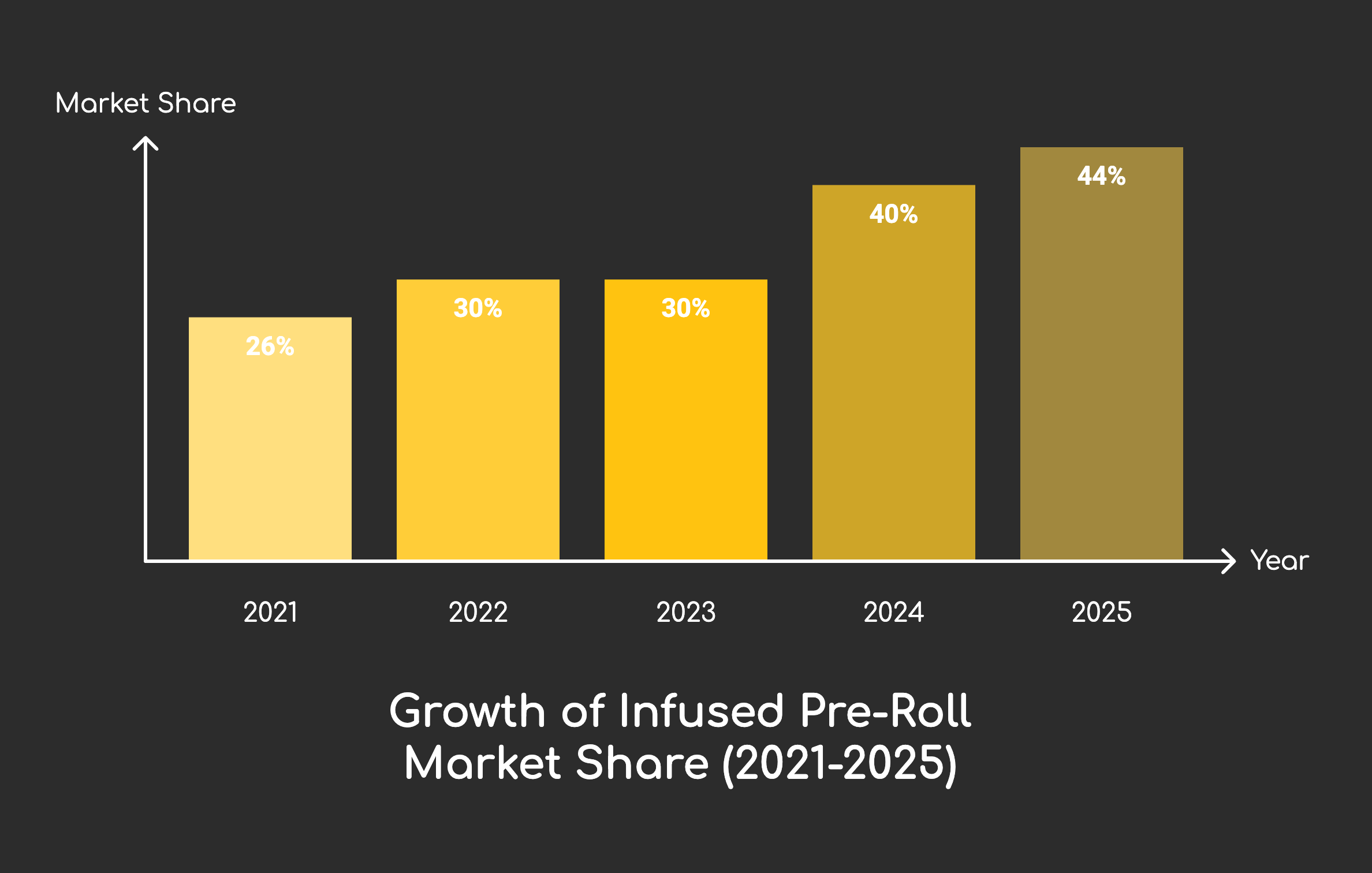

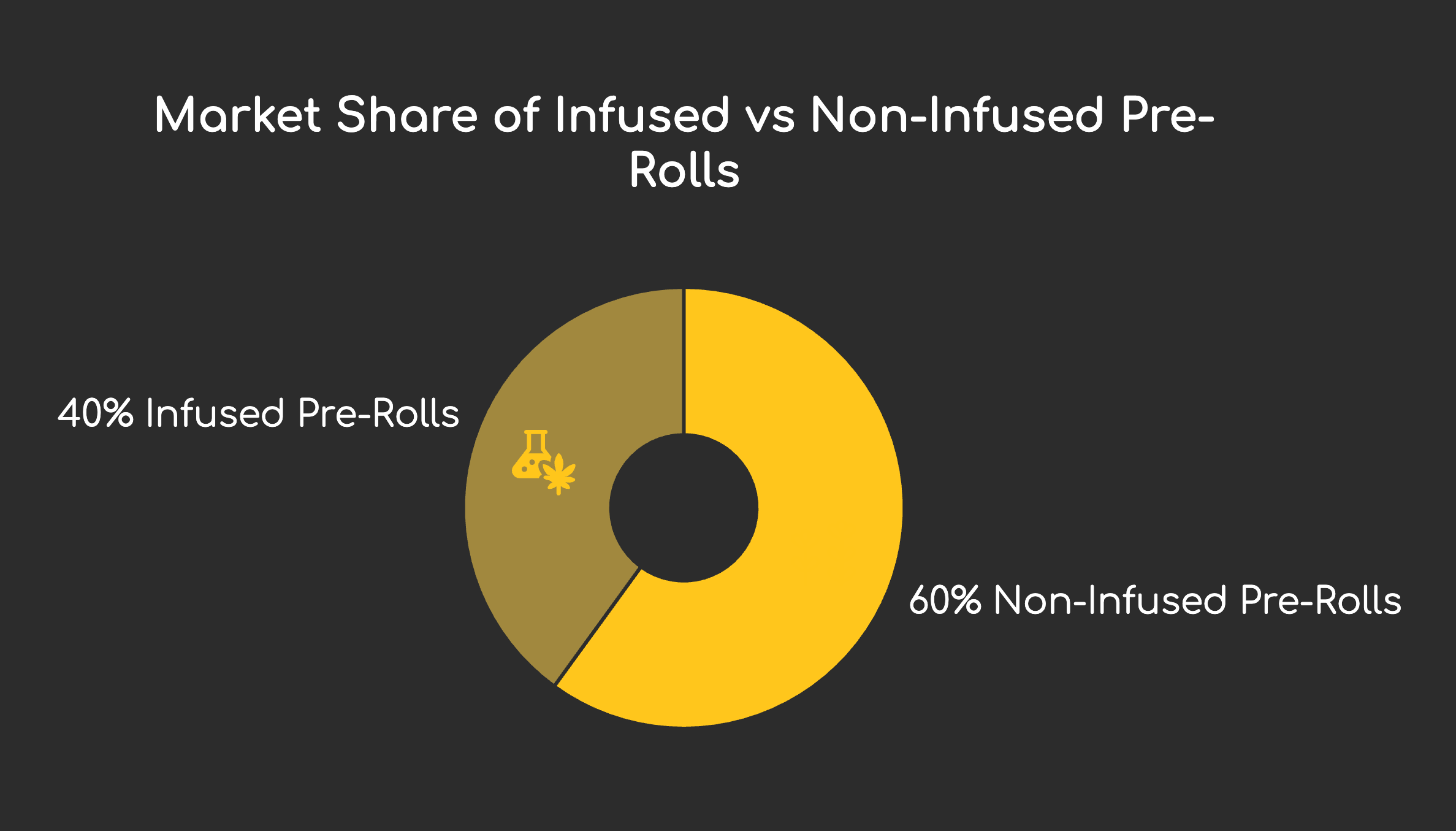

Pre‑rolled joints have evolved from convenience products into one of the cannabis sector’s fastest‑growing categories. In the past few years, pre‑rolls captured a growing share of total cannabis sales, and infused varieties now account for roughly 40 % of all pre‑rolls sold. A new generation of consumers is chasing potency and flavour rather than simply convenience. Automation and improved equipment have removed production bottlenecks, enabling producers to scale infused pre‑rolls while maintaining consistency. This guide combines decades of industry insight with the latest data and competitor analysis to help you create outstanding infused pre‑rolls in 2025.

Market trends: why infused pre‑rolls dominate

The pre‑roll category isn’t just growing; it’s becoming a core part of the cannabis supply chain. Several factors explain the surge:

- Potency, flavour and affordability drive demand. Consumers increasingly seek bold terpene profiles and higher THC concentrations. Infused products allow brands to stretch flower and distillate further while delivering value. Automation has lowered production costs, making five‑packs of infused joints cost roughly what two singles cost just two years ago.

- Multipacks and petite sizes are hot. In 2024 and 2025, multipacks and petite “dogwalker” joints climbed the charts. Top brands like Jeeter, Stiiizy and Dogwalkers report that all of their best‑selling SKUs are infused multipacks.

- Infusion is here to stay. Industry experts predict an 80/20 rule: a small proportion of SKUs (the infused, premium ones) will drive the majority of sales. As consumer tastes mature, flavour, quality and consistency become differentiators.

Consumer insights & demand drivers

The meteoric rise of infused joints isn’t just a matter of novelty—it’s rooted in shifting consumer behaviour. Bold flavours and creative blends are increasingly important, mirroring trends in tobacco and beverages. Lower prices for infused multipacks have also broadened access. At the same time, demand for full‑flower connoisseur joints is resurging as consumers trust brands that prioritise quality. Operators like Xylem suggest complementing traditional flower sales with pre‑rolls to maximise margins.

Multipacks are reshaping the market

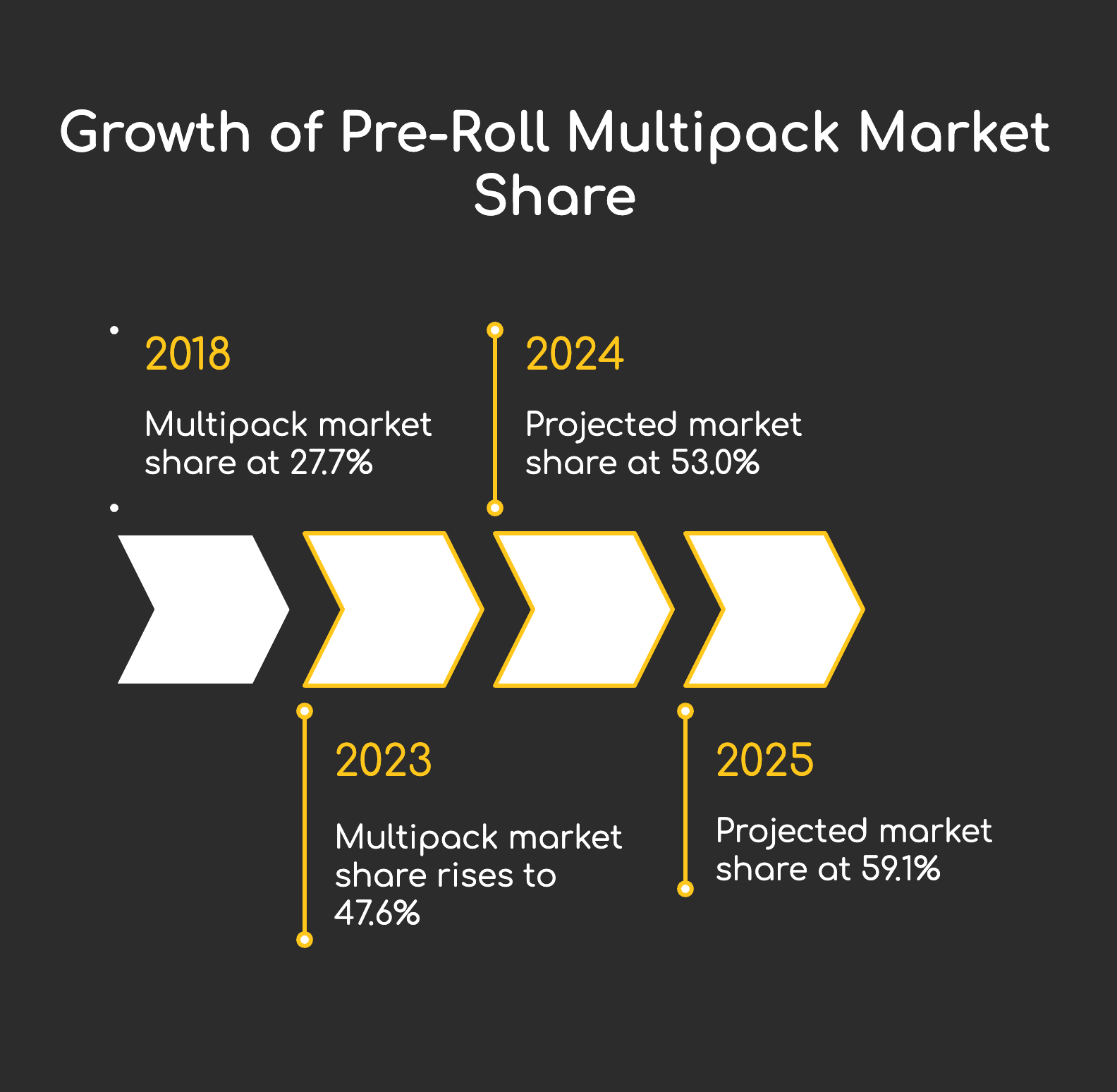

Multipack formats—especially five‑packs of petite dogwalker joints—have propelled category growth. CannaCon reports that multipacks grew from 27.7 % of the pre‑roll market in 2018 to 47.62 % in 2023. Multipacks appeal to price‑sensitive consumers by offering a better cost‑per‑joint, and they give brands a way to showcase multiple flavours or infusion levels in one package. When planning your product line, consider whether sampler packs, limited‑edition flavour flights or dogwalker multipacks could expand your audience.

To visualise the current state of the category, the pie chart below shows that infused pre‑rolls already make up about two‑fifths of all pre‑roll sales. A line chart illustrates how this share has climbed steadily over the past five years.

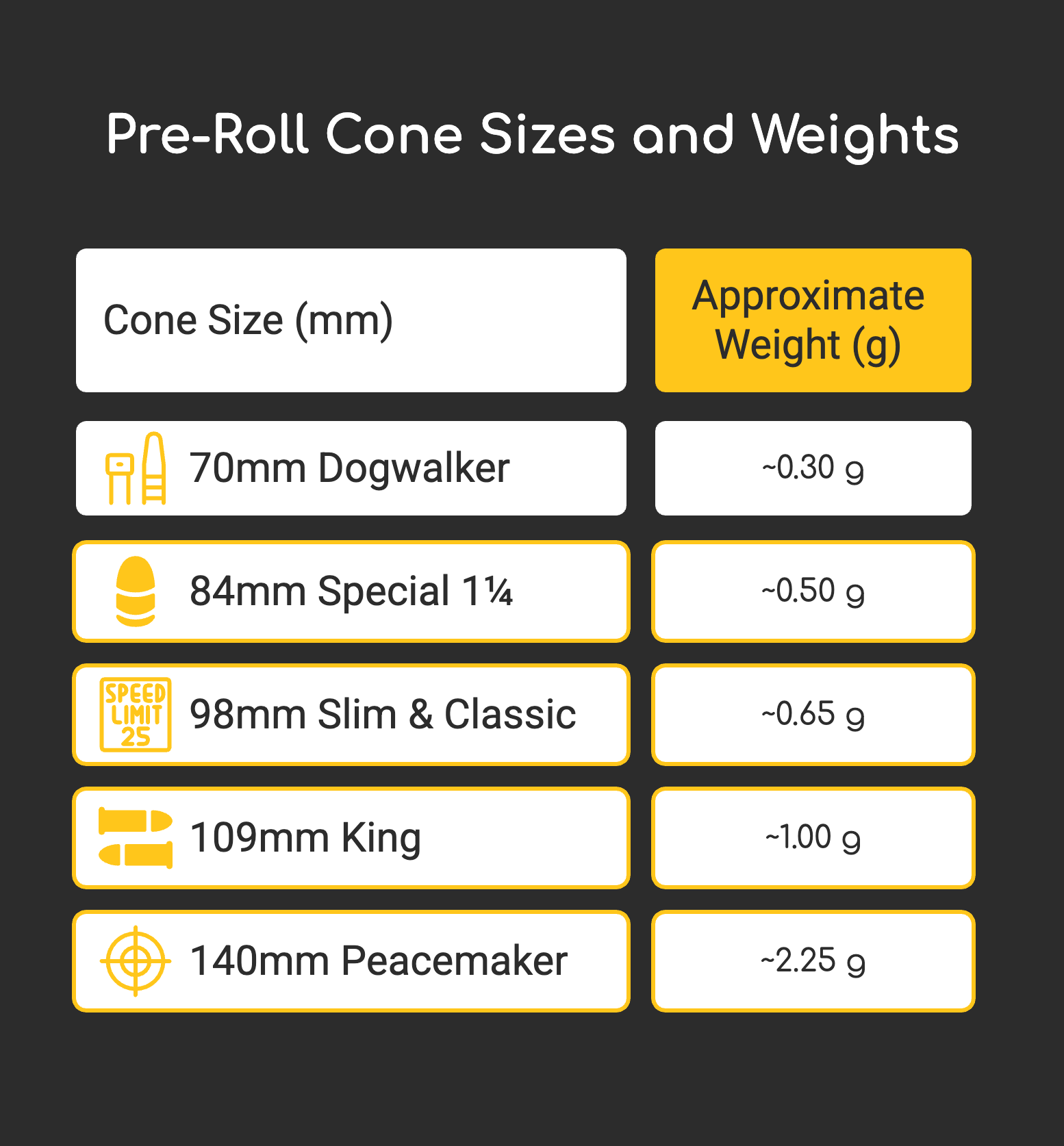

Select the right cone size and wrap

Before grinding or infusing, decide how much material you want in each joint. Humboldt Filling Machines’ sizing guide notes that cones and tubes come in many lengths and volumes. Choosing the right size ensures the dosage and experience match your brand’s intent. Common options include:

- 70 mm “Dogwalker” cones (0.25–0.35 g) – compact and ideal for single‑serve experiences; these petite joints are rapidly gaining popularity.

- 84 mm “Special 1 ¼” cones (0.5 g) – classic size for half‑gram joints.

- 98 mm “Slim” and regular/classic cones (0.5–0.75 g) – these versatile sizes suit a wide range of blends.

- 109 mm “King” cones (1 g) – the go‑to for one‑gram connoisseur joints.

- 109 mm large‑crutch cones (1.5 g) and 140 mm “Peacemaker/Party” cones (2.25 g) – for party‑sized experiences.

| Size & description | Approx. weight (g) | Typical use |

|---|---|---|

| 70 mm “Dogwalker” | 0.25–0.35 | Quick solo breaks or sampling a new blend |

| 84 mm Special 1 ¼ | 0.5 | Casual half‑gram joint for personal enjoyment |

| 98 mm Slim/Classic | 0.5–0.75 | Classic joint; shares well between two people |

| 109 mm King | 1.0 | Longer sessions; ideal for sharing or a robust experience |

| 140 mm Party | 2.25 | Large group sessions or celebrations |

This table summarises popular cone sizes, their weights and the occasions they suit. When designing your line, align sizes with customer use cases: petite dogwalkers for microdosing, classic kings for one‑gram connoisseur joints and party cones for communal experiences. The Fill N’ Fold Work Tray and All‑In System let you switch between these sizes effortlessly.

Wraps and tubes vary in length as well; for example, 84 mm artisan tubes (0.5 g), 105 mm “Slim” palm wraps (1.5 g) and 129 mm wood‑tip wraps (2 g). Pre‑rolls using wood‑tip wraps command a premium but may require specialised machines for proper sealing.

To explore tray options for each size, check our Fill N’ Fold Work Tray or All‑In System pages, where you can view 70 mm, 84 mm, 98 mm and 109 mm trays together.

Prepare your flower correctly

Cure and store with care

High‑quality pre‑rolls begin long before grinding. The flower must be properly dried and cured to prevent mould and preserve terpenes. Maintain relative humidity between 55 % and 62 % during curing to avoid brittleness, and store cured buds in airtight containers away from light. Over‑dry buds produce harsh smoke; overly moist buds encourage mould growth.

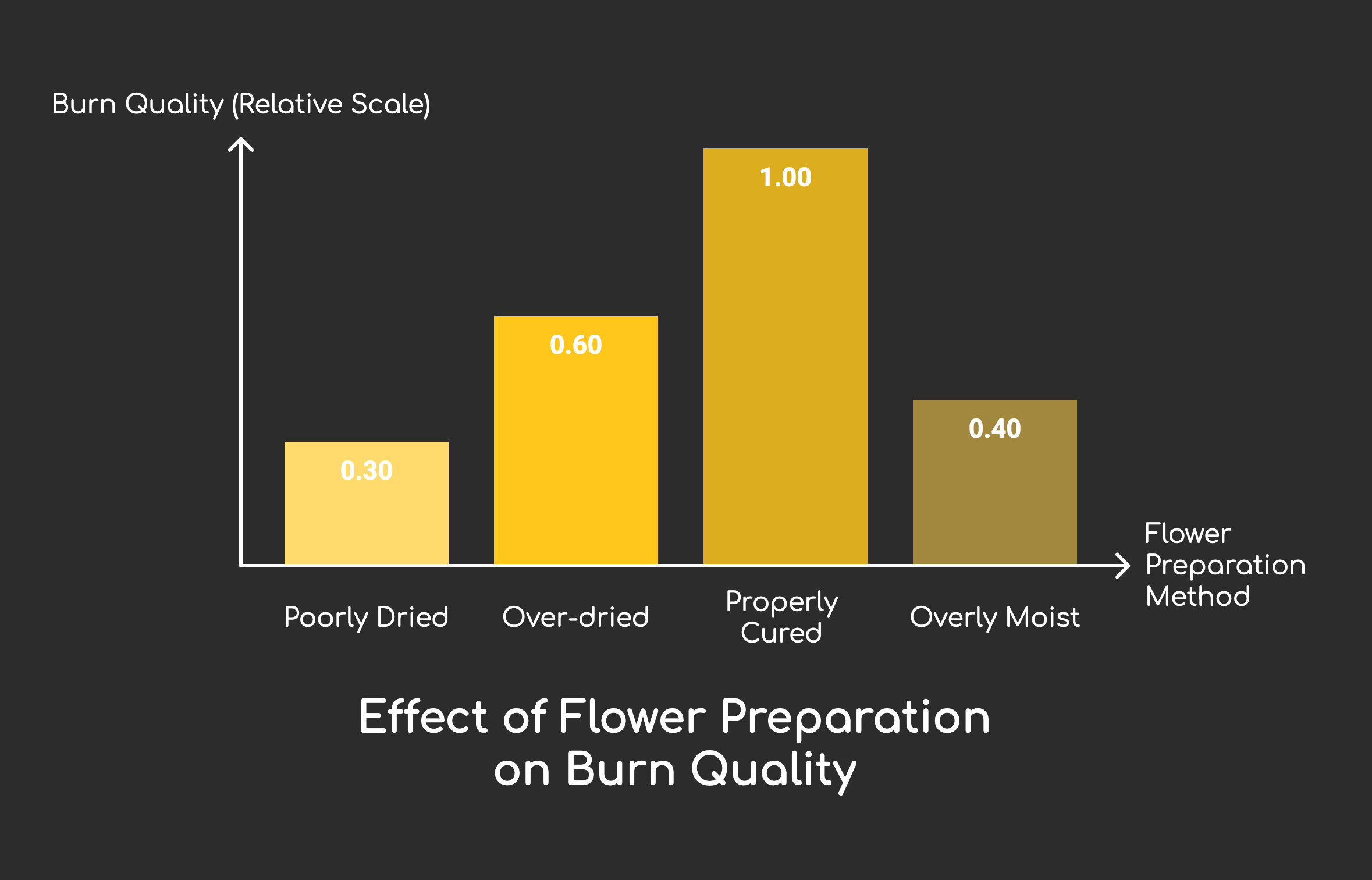

Why curing matters: burn quality vs. humidity

The following chart illustrates how varying moisture levels impact burn quality. Properly cured flower—maintained at 55–62 % relative humidity—delivers the smoothest burn. Over‑dried or overly moist material results in a hot, uneven or sputtering burn. Use airtight containers with humidity packs to maintain optimal conditions.

Grind gently and consistently

Grinders for pre‑roll production operate at low revolutions per minute (RPM) with high torque to avoid heating the buds. High‑RPM devices like blenders pulverise buds into dust, degrading cannabinoids and terpenes. Aim for a medium‑fine particle size that packs evenly; uneven particles create inconsistent weights.

Don’t skip sifting

After grinding, run the material through a sifter. Sifting removes stem fragments and overly fine particles that can make pre‑rolls burn hot or tear the paper. This step acts as quality control and improves airflow, ensuring smooth burning. Our Sifting Kit includes dual screens to grade material and produce a consistent, even grind, while tools like the Tube Brush simplify cleanup between runs.

Abstract illustration of swirling green lines around a circular form to represent grinding and sifting

Photo of the Fill N’ Fold Sifting Kit, which includes dual screens for grading material

Choose equipment that supports infusions

Infused pre‑rolls are stickier and more viscous than standard joints, so appropriate equipment is essential. Automated or semi‑automated machines ensure consistent weights and pack the infusion evenly. When selecting equipment, consider:

- Production volume: choose single‑cone fillers for craft batches or high‑capacity machines when scaling up. Manufacturers are doubling or tripling capacity to keep up with demand.

- Compatibility with cone sizes: ensure your machine supports your preferred work tray sizes (70 mm, 84 mm, 98 mm and 109 mm). Adjustable trays simplify changeovers between sizes and reduce downtime.

- Integration with infusion systems: pair your filler with adjustable metering trays and press tools that can handle sticky material. Some manufacturers now offer dedicated infusion stations that inject resin slugs at precisely calibrated positions inside the cone, creating a visible “spot” that serves as a potency cue for consumers.

- Cleaning and maintenance: infused joints leave sticky residue. Keep your machine running smoothly with a sifting kit, catch tray, scraper and bucket & lid to catch and clean up material between batches.

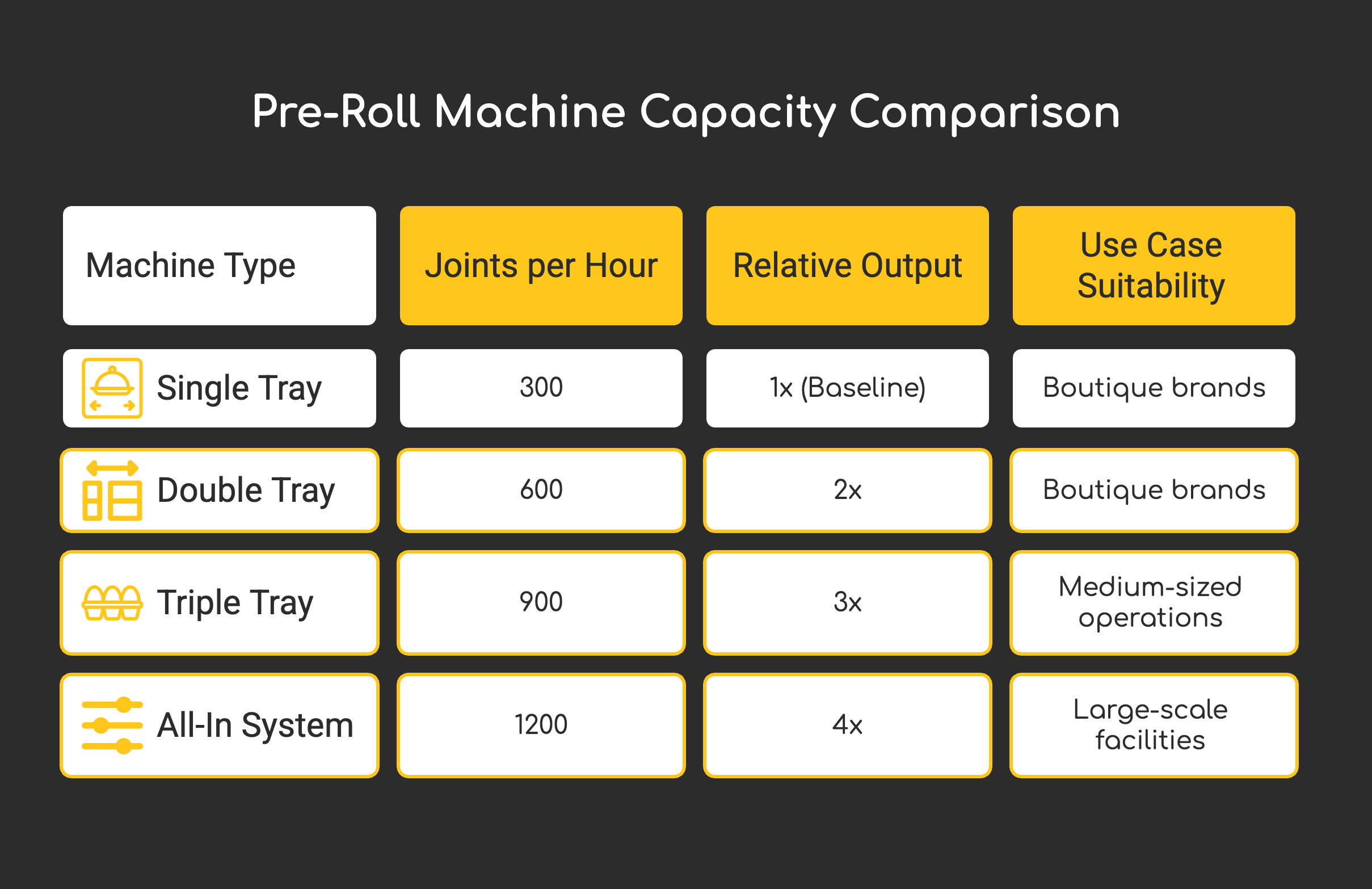

Compare machine capacities

Different machines deliver different throughputs. The bar chart below compares approximate joints per hour for the Single Tray, Double Tray, Triple Tray and All‑In System. Use it to gauge which machine suits your production goals.

Photo of the Fill N’ Fold All‑In System including work trays, metering trays, press tools, buckets and accessories

Automation and training matter

Automation removes human error and ensures consistency across thousands of joints. Suppliers like RollPros and Xylem provide custom training that covers post‑harvest curing, equipment operation, infusion techniques and even in‑store marketing. Consider partnerships that include training and support to maximise yield and ensure your staff understands infusion methods.

Explore infusion methods and formulation

Infusion techniques range from simple distillate drizzles to complex hash holes. Each method affects potency, flavour and burn.

Choose your concentrate

- Distillate: clear and flavourless; delivers high THC but little terpene complexity. A thin stripe along the paper or the inside of the cone adds potency without clogging.

- Live resin and sauce: retain native terpenes, adding aroma and flavour but with lower THC concentration. They can be mixed with ground flower or applied as a “snake” along the joint.

- Rosin and hash holes: rosin slugs or worms of hash/rosin rolled into the joint create a true hash hole. According to industry experts, rosin should not be heated and injected because heating kills flavour. Instead, roll a worm of rosin and place it inside the flower for a smooth burn.

- Kief and diamonds: dusting the outside of a finished joint with kief or crushed diamonds adds potency and visual appeal. Ensure even coating and test burn to avoid runs.

Comparing infusion techniques

| Infusion method | Description | Pros | Cons |

|---|---|---|---|

| Distillate stripe | Apply a thin line of distillate along the inside of the cone or paper | High potency; minimal flavour impact; easy to control | Lacks terpene complexity; risk of runs if placement is off |

| Live resin mix | Blend live resin or sauce with ground flower before filling | Retains natural terpenes; rich flavour profile | Lower potency than distillate; mixing can be messy and requires proper equipment |

| Rosin hash hole | Place a worm of rosin or hash in the center of the cone | Premium experience; preserves flavour and aroma | Labour intensive; concentrate costs are higher; risk of uneven burn if not balanced |

| Kief or diamond coating | Roll the finished joint in kief or crushed THCa diamonds | Dramatic visual appeal; boosts potency | Outer coating can burn irregularly; can be messy and may require special packaging |

This table summarises popular infusion methods, highlighting their advantages and drawbacks. Experiment with different techniques to find the right balance of potency, flavour and ease of production. Remember to train your team on infusion best practices and adjust your grind and fill techniques accordingly.

Infusion best practices

- Dose carefully: start with lower concentrate loadings and adjust based on potency goals and target customer segment.

- Pair complementary flavours: match terpene profiles of extract and flower to enhance taste and aroma.

- Distribute evenly: mix extract homogeneously through the ground material or place a stripe in a way that minimises clogging and ensures a uniform burn.

- Test and refine: perform test burns to confirm that the infusion doesn’t create runs or harsh flavours. Adjust grind size or concentrate placement as needed.

Package and label with compliance in mind

Packaging is not just about aesthetics; it’s a regulatory requirement. The California Department of Cannabis Control (DCC) specifies that cannabis products must be child‑resistant, tamper‑evident and resealable if they contain multiple servings. Packaging should also avoid designs attractive to children and cannot include unverified health claims or county names unless 100 % of the cannabis was grown there. In addition:

- Use the universal cannabis symbol on the primary panel and include required warnings and THC content.

- Consider sustainability: many states are moving towards post‑consumer recycled content requirements. Using recyclable materials and minimal packaging not only improves sustainability but can reduce costs.

- Brand storytelling: premium finishes, metallic accents and window cut‑outs can elevate perceived value. However, ensure all materials and adhesives are food‑safe and comply with state regulations.

Visualising compliance priorities

Bar chart summarising key packaging compliance features

Beyond legal compliance, packaging innovation can enhance user experience. Consider flip‑top tins, slider boxes or post‑consumer recycled paperboard for multipacks. Transparent tubes and corked glass jars allow customers to see the product while signalling premium quality, but check your state’s opacity rules. For sustainability, look into compostable papers and plant‑based plastics. Whatever you choose, leave room for warnings, the universal symbol and a QR code linking to your Certificate of Analysis.

Sustainability & eco‑conscious production

Environmental stewardship is becoming a major differentiator in the cannabis space. As consumers demand greener products, brands are exploring ways to reduce their carbon footprint and waste. Consider these approaches:

- Use recycled and biodegradable materials. Swap traditional plastic tubes for recycled paperboard, hemp‑based plastics or compostable PLA. For multipacks, opt for tins or cardboard boxes that can be reused or easily recycled.

- Minimise packaging. Avoid excessive layers and oversized containers. Use labels printed with soy‑based inks and water‑based adhesives.

- Implement closed‑loop recycling. Offer take‑back programs where customers can return empties for a discount on future purchases. Partner with recycling companies that specialise in cannabis packaging.

- Power your facility sustainably. Invest in renewable energy sources, efficient HVAC systems and water recycling. Many consumers appreciate brands that demonstrate environmental responsibility.

Highlighting your sustainable practices can resonate with environmentally conscious shoppers and align with broader corporate social responsibility goals.

Marketing, branding and consumer education

In a crowded market, quality and storytelling are critical. Experts note that connoisseur joints – full‑flower pre‑rolls crafted with care – are reshaping perceptions. Infused joints can be premium or poor depending on how they’re made. Education helps consumers understand why your infused joint stands out. Consider these strategies:

- Tell your infusion story: highlight the type of extract and how it complements the flower. Visible resin slugs, when placed near the paper, can become a marketing cue that signals potency.

- Invest in in‑store activations: training budtenders and providing sample joints or demo videos helps them communicate your product’s benefits.

- Use QR codes: link to certificates of analysis, strain information or videos showing your infusion process. Transparency builds trust and differentiates your brand.

- Leverage multipacks and petite formats: offer dogwalker‑sized multipacks for sampling multiple flavours or potency levels at an attractive price point.

Expanding your marketing toolkit

Successful brands go beyond basic advertising to build community and trust. Consider the following initiatives:

- Cultivate a brand story. Share the origin of your flower, your infusion techniques and the people behind your brand. Consumers respond to authenticity and craftsmanship.

- Engage on social media. Post behind‑the‑scenes videos of grinding, sifting, filling and infusion. Use polls to gauge interest in new flavours or sizes. Comply with platform policies and local advertising regulations.

- Collaborate with budtenders. Host training sessions and product knowledge seminars so retail staff can explain your infusion methods. Offer incentives for top sellers.

- Leverage experiential marketing. Set up pop‑ups at dispensaries or events. Provide sample joints and encourage feedback. Demonstrations of your equipment can attract attention and highlight your commitment to quality.

- Educate through content. Publish blog posts (like this one), guides and videos on curing, grinding, sifting and infusion. Use QR codes on packaging to link directly to educational material. Transparency builds loyalty and sets your brand apart.

Abstract illustration representing cannabis marketing and education

Key takeaways

- Infused pre‑rolls dominate growth. They already account for roughly 40 % of pre‑roll sales and are expected to drive the majority of future growth.

- Choose the right cone size. Dogwalker, half‑gram, three‑quarter‑gram, one‑gram and party cones each suit different experiences. Our work trays make switching between sizes simple.

- Prepare flower meticulously. Cure to 55–62 % humidity, grind at low RPM and sift out stems.

- Use equipment built for infusions. Match production scale to your machine (single vs multi‑tray), integrate adjustable metering and keep cleaning supplies on hand.

- Experiment with concentrates. Distillate stripes, live resin, rosin worms and kief dustings each offer unique flavour and potency; test and refine.

- Stay compliant and tell your story. Child‑resistant, tamper‑evident packaging and clear labels are mandatory. Marketing and education build loyalty in a competitive market.

By combining data‑driven sizing, careful flower preparation, specialised equipment and thoughtful infusion and marketing strategies, you can craft pre‑rolls that stand out in 2025’s booming infused joint market. Keep experimenting with flavours and formats, stay compliant, and educate your customers—the future of pre‑rolls has never been more exciting.

Disclosure: This guide is for educational purposes only. Ensure you follow all regional regulations when producing and packaging cannabis products.